Small Caliper Type Automatic Welding Machine For Pipe To Pipe

Application:

Parameter:

insert memory: 100 welding manner;

Pipe diameter: φ16 mm ~φ300 mm.

Advantage

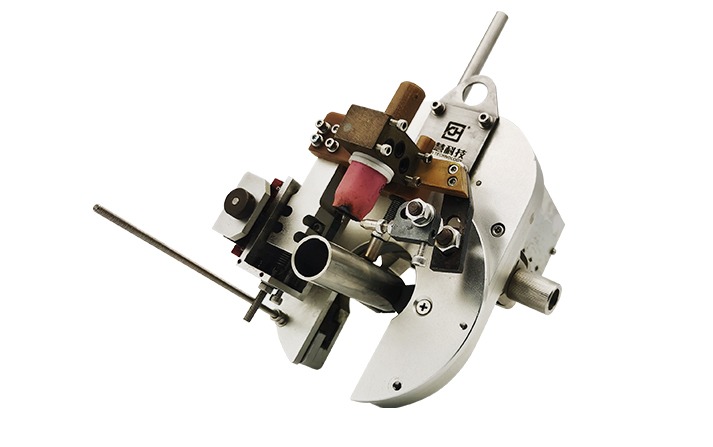

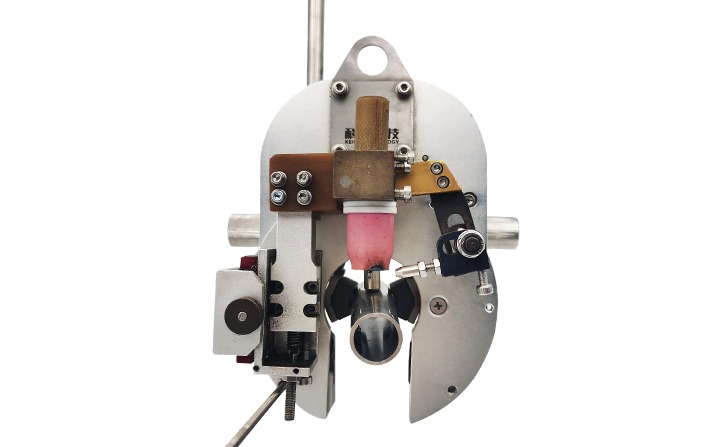

KHGK Pipe-Pipe Automatic Welding Machine(Open Head Orbital Welding) is a specialized automatic orbital pipe welding machine, It can automatic welding 360 degrees around the pipe, There are 6 welding heads at the same time, which can adapt to the welding of different sizes of pipes.

KHGK could address the issue of operator error in gas tungsten arc welding(GTAW).

KHGK is composed of the power supply,control system,cooling system and the welding head.

KHGK could process carbon steel, alloy steel, stainless steel and titanium alloy.

KHGK could do auto welding of tube to tube, tube to flange, tube to elbow and tube to tee.

KHGK is designed with tiny welding head, very convenient to operate in narrow tube installation site. Meanwhile, its TIG welding makes high seal performance.

Therefore, KHGK orbital welder is widely adopted in the installation of plants such as water /oil/gas plant, food& alcohol plant,chemical industry, medicine and other industries.

Parameter

| Welding head | KHGK16-40 | KHGK36-90 | KHGK70-160 | KHGK140-230 | KHGK210-300 | ||||

| Welding Speed(r/min) | 0.4~3 | 0.2~2 | 0.1~1 | 0.07~0.5 | 0.07~0.5 | ||||

| Suitable Dia.(mm) | 16~40 | 36~90 | 70~160 | 140~230 | 210~300 | ||||

| Electrode Dia.(mm) | 1.6/2.4 | 2.4 | 2.4 | 2.4 | 2.4 | ||||

| Swinging function (OSC function) | |||||||||

| Amplitude(mm) | — | ±8 | ±8 | ±8 | ±8 | ||||

| Speed(mm/s) | — | 0.5~10 | 0.5~10 | 0.5~10 | 0.5~10 | ||||

| Dwell time(s) | — | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~10 | ||||

| Arc Voltage Control (AVC function) | |||||||||

| Amplitude(mm) | — | 8 | 8 | 8 | 8 | ||||

| Speed(mm/s) | — | 2.5 | 2.5 | 2.5 | 2.5 | ||||

| Filler Wire | |||||||||

| Wire Dia.(mm) | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | 0.8/1.0 | ||||

| Speed(mm/min) | 0~1500 | 0~1500 | 0~1500 | 0~1500 | 0~1500 | ||||

| Welding Torch | |||||||||

| Adjust Angle of welding torch | 0°~45° | 0°~45° | 0°~45° | 0°~45° | 0°~45° | ||||

| Rated input voltage | 380V±10% |

| Rated welding voltage | TIG welding, 22.6V |

| Phase number | three-phase |

| Rated power input | 13.2KW |

| Argon flow | 8~12L/min |

| Rated voltage no-load | 70V |

| Frequency | 50/60HZ |

| Welding current adjusting range | 4~400A |

| Voltage allow fluctuating range | 380V±10% |

| Rated duty cycle | 400A 60% |

| 250A 100% | |

| Rated input capacity | 13.9KVA |

| Built-in memory space | 100 groups of welding code |

| Each set can segments | 1~12 section |

| Pulse frequency | 0.5~500HZ |

| Preheating time | 0.1~25S |

| Current rise time | 0.1~25S |

| Current decrease time | 0.1~25S |

| Cooling water pressure | 1.2kgf/㎡ |