Orbital Weld Head For 3-180mm Steel Tube Welding

Application:

Advantage

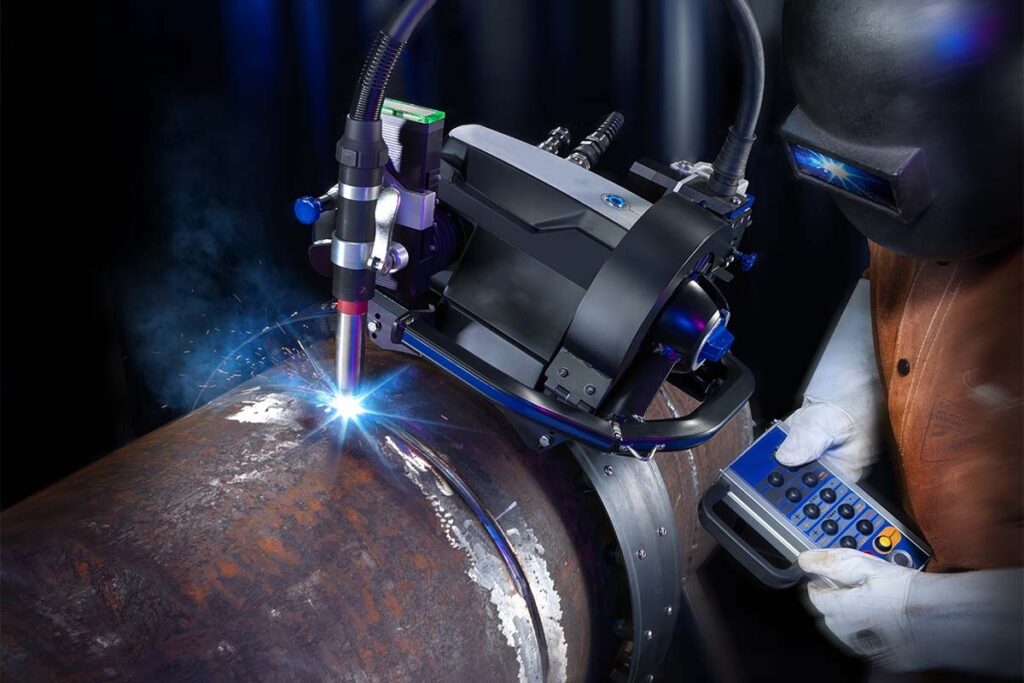

1. Mature technology, sealed welding, perfect welded pipe.

2. Accurate welding. Using IGBT inverter DC pulse and TIG power supply, combined with advanced control technology, to ensure perfect finished products.

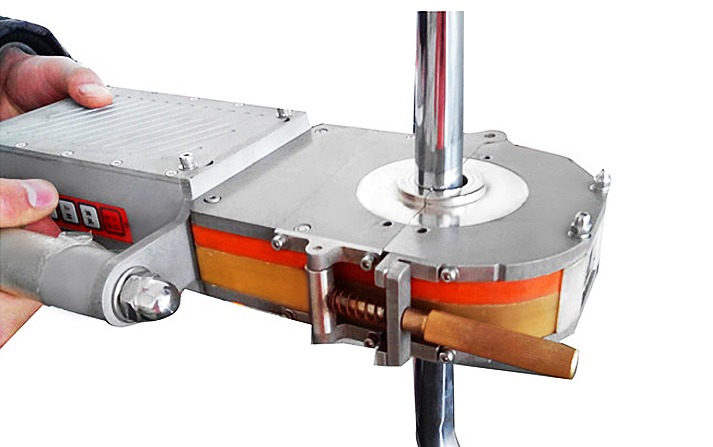

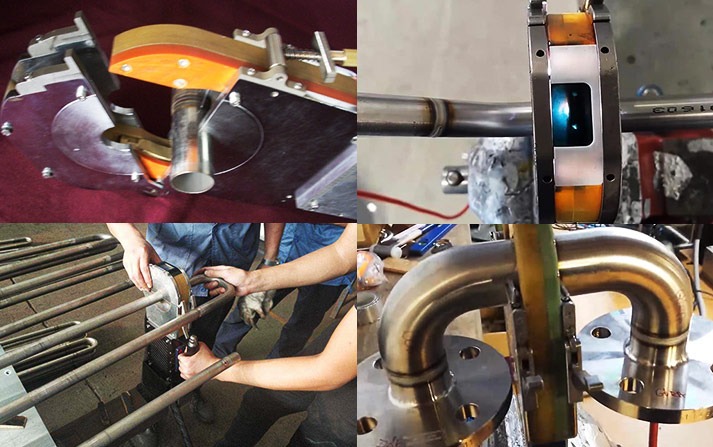

3. 7 types of welding heads to adapt to different requirements. Customers can choose the welding head according to the pipe size and space. You can also purchase a few different heads to match the control system to save costs.

4. Digital programming and LCD touch. The system can store 100 different process specifications, each of which can be divided into 6 parts. You can use it anytime.

Parameter

| Technical Parameter Of Digital Welder | |||

| Outer diameter of weldable pipe | φ3 mm ~φ180 mm | Rated load duration | 60 % |

| Power control mode | IGBT | Rated no-load voltage | 78 V |

| Power | 380V 50 / 60 Hz | Rated welding voltage | 22.6 V |

| Voltage allows range of fluctuation | 380 V ± 10 % | Adjustment range of welding current | 5 ~ 300 A |

| Rated input capacity | 13.9 KVA | Pulse frequency | 0.5 ~ 500 Hz |

| Rated input power | 9.5KW | Pulse duty ratio | 5~95% |

The KHGC have 7 types to suitable for welding different pipe diameters. Customer could choose it by your siae of need welding pipe and space.

It’s also could buy a set of control system and different welding head to used for different pipe.

| Welding Head Models And Parameters | ||||||

| Model | KHGC 20 | KHGC 34 | KHGC 63 | KHGC 89 | KHGC 114 | KHGC180 |

| Weld speed (rpm) | 0.6-10 | 0.6-10 | 0.3-5 | 0.1-2.5 | 0.1-2.5 | 0.1-2.5 |

| Suitable Dia (mm) | 3-20 | 10-34 | 12-63 | 16-89 | 20-114 | 51-180 |

| Electrode Dia (mm) | 1.6 | 1.6/2.4 | 1.6/2.4 | 1.6/2.4 | 1.6/2.4 | 1.6/2.4 |