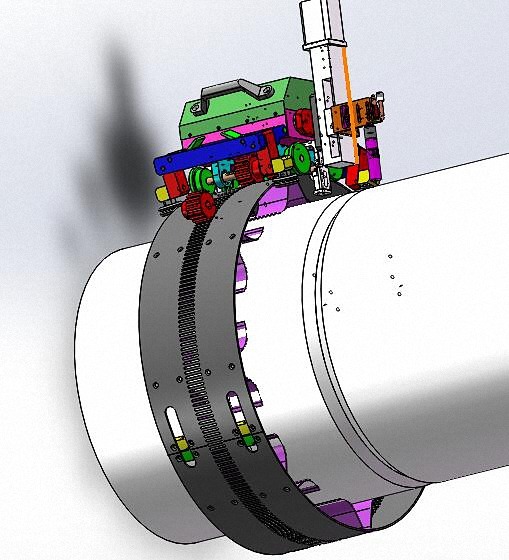

Large Pipe Construction – Track Welding

Application:

Parameter:

Advantage

1. Prepare for 2 minutes before welding, time period, easy to install

2. Weld formation to meet the flaw detection standard

3. Can be welded at the same time with two heads, high efficiency

4. Imported, the product quality is excellent

KHR portable quenching medium cooling performance detector is widely used to test and compare the performance of different media under the standard conditions of the real laboratory. It is more suitable for the wake-up monitoring of the cooling bath liquid in the field working environment. It is to improve the quality of heat treatment products, reduce and eliminate waste products. Effective means.

1. The maximum cooling rate, the maximum cooling rate, the cooling rate at 300 °C, the cooling to 600 °C, and the cooling performance of the water-based and oil-based cooling media can be tested under the field operating conditions and laboratory standards. Cool down to 400 ° C, cool to 200 ° C time.

2. This machine can store 64 test results for retrieval.

3. Four test results can be stacked on the same map for comparative analysis.

4. To quantify the curve, you can overlay the grid on the curve or display the results as a tabular form.

5. With communication interface and computer-specific software, the test results can be transmitted to an external computer for further analysis and evaluation.

Alternative function:

1. Using special probes to test the performance of cooling medium such as high speed steel quenching and stainless steel solid solution.

2. Perform heating and cooling process testing, such as induction hardening, heat treatment process inspection of large castings and forgings.

3. Determine the performance of the cooling medium of the water-based quenching medium under different stirring strengths (Tensi method cooling standard device).

Parameter

| Welding Method | MAG/MIG | ||

| Protective Gas | carbon dioxide + argon mixed gas, depending on the use of the wire | ||

| Power Supply | 110V/240V, can be changed according to site conditions | ||

| Welding Wire | ordinary welding wire or flux cored wire, 0.9mm-1.4mm | ||