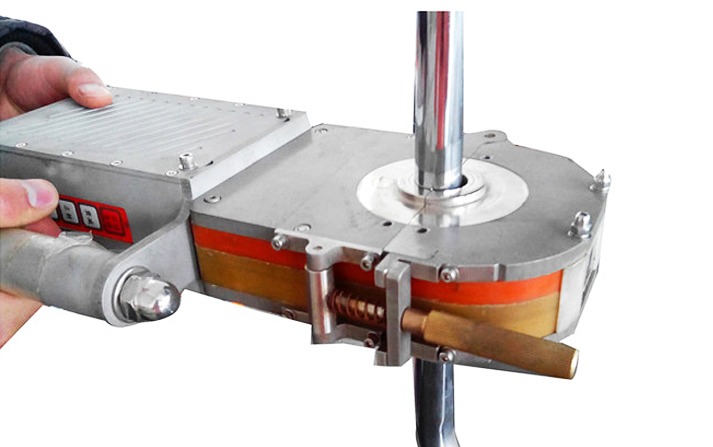

Large orbital automatic welding machine

Application:

Parameter:

Pipe outer diameter: φ3mm ~φ180mm;

Protecting air: argon.

Advantage

1. Double clamping positioning, good positioning effect, no need to locate spot welding, improve welding efficiency.

2. Pulse power supply, closed design of the welding head, good protection effect, uniform and beautiful weld seam.

3. Lightweight structure design, suitable for assembly site with small space.

Description:

KHGC Closed Head Orbital Welder is a specialized auto arc welding machine whereby the arc is rotated mechanically through 360° around a static work piece of tube to tube with tube specification φ3~φ114 mm and tube thickness 0.8~3mm.

KHGC could address the issue of operator error in gas tungsten arc welding(GTAW).

KHGC is composed of power supply, control system,cooling system and welding head.

KHGC could process carbon steel, alloy steel, stainless steel and titanium alloy.

Parameter

| Dimension of Welding Heads(mm) | |||||

| KHGC12 | KHGC34 | KHGC63 | KHGC89 | KHGC114 | |

| A | 62 | 92 | 130 | 156 | 204 |

| B | 35 | 53 | 71.5 | 88 | 110 |

| C | 95 | 135.3 | 174.5 | 218 | 280 |

| D | 265 | 300 | 330 | 384 | 446 |

| E | 20 | 40 | 43 | 43 | 43 |

| F | 12.5 | 24 | 25.5 | 26 | 26 |

| Rated input Voltage | 380 V/415V±10% |

| Rated input capacity | 16.0 KVA |

| Voltage allow fluctuating range | ± 10 % |

| Phase | Three phase |

| Frequency | 50 / 60 Hz |

| Rated welding voltage | TIG welding, 22V/32V |

| Rated voltage no-load | 57V/62V |

| Power control mode | IGBT Inverter control |

| Welding current adjust range | DC 5~300A |

| Rated load sustained rate | 40% |

| Current rise time | 0.0 ~ 15.0 s |

| Weldable wall thickness | 0.8-3mm |

| Preheating time | 0.0 ~ 0.1 s |

| Current decline time | 0.0 ~ 25.0 s |

| Pulse frequency | 0.5 ~ 500 Hz |

| Duty ratio adjustment range | 15% ~ 85% |

| Cooling type | Water cooling/ Air cooling |

| Weight | 19 kgs |

| Size (L×W×H) | 450×210×420 mm |

| Insulation class | H |