KH 3 in 1 Auto Pulse Argon Arc Orbital Welder

Application:

Parameter:

Advantage

1.To addresses the issue of operator error in GTAW / TIG . computer-controlled process runs with little intervention from the operator.

2.Three-in-one Multi-function, It is wildly used for KHGK, KHGC, KHB12-80 series 11 different type of orbital welding heads.

3.To guarantee high quality repeatable welding. a successful programming monitors variables and performs periodic samples during its test welding. LCD touch screen, easy to input.

4.Intelligent welding . 100 successful programming stored in PLC, just pick one.

5.High productivity. 2-3 times higher than conventional TIG welding.

6.10 hours continuous welding. qualified welding head and power and water cooling system make it.

7.Car-integrated design, freedom of movement.

8.Small space of scientific design

KH-315A Multi-function Automatic TIG welder is a power source with Multi-function control system, which suits for KHGC, KHGK and KHB12-80 series various of tube orbital welding heads and Tube to tube sheet orbital welding head.

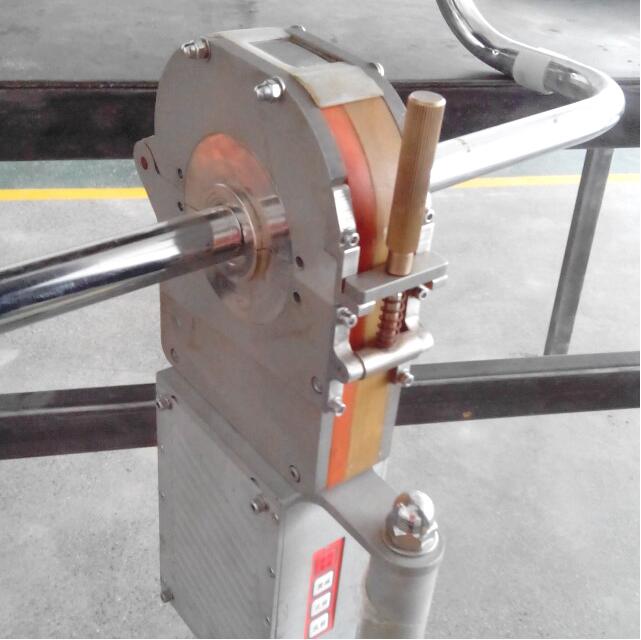

1)KHGK series open-frame orbital welding heads are used to weld tube OD 16mm – 300mm, and the tube wall-thickness is 1.5mm – 20mm.

2)KHGC series closed- frame orbital welding heads are used to weld tube OD 3mm – 180mm, and the tube wall-thickness is less than 3mm.

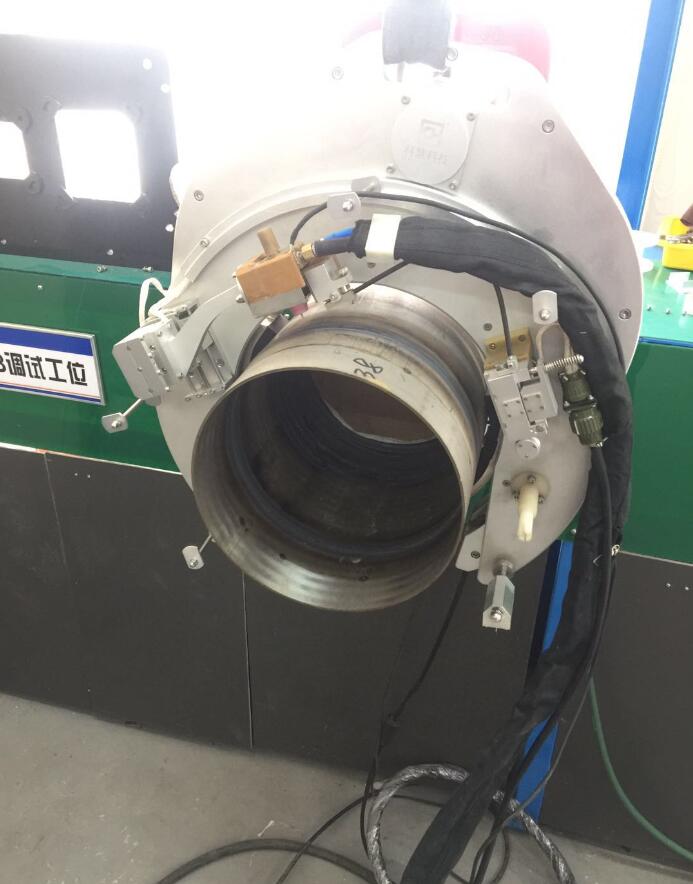

3)KHB12-80 series Tube to tube sheet orbital welding head is used to weld tube to tube-sheet, the tube OD 12 – 80mm, Max. 89mm, and tube thickness 1 – 6.5mm.

NOTES:

1.the tubes must be standard type, the deviation must be within machine tolerance.

2.A trained operator is necessary to make sure its normal work.

Parameter

| No. | Item | Parameters |

| 1 | Power control mode | IGBT inverter control |

| 2 | Rated input voltage&range | AC 200/220V ±10%(Can be changed to 3 phase, 380V) |

| 3 | Power frequency and phase no. | 50/60Hz, single phase |

| 4 | Rated input volume | 9.0KVA |

| 5 | Rated input power | 5.9KW |

| 6 | Rated load duration | 40% |

| 7 | Rated floating voltage | 65V |

| 8 | Rated welding voltage | 19V |

| 9 | Welding current(base current) | 4~300A |

| 10 | Pulse current | 4~300A |

| 11 | Starting current | 4~300A |

| 12 | Crater arc current | 4~300A |

| 13 | Pulse frequency | 0.5~30Hz |

| 14 | Pulse duty cycle | 5~95% |

| 15 | Rise time | 0.0~20S |

| 16 | Fall time | 0.0~20S |

| 17 | Advance air delivery time | 0.0~20S |

| 18 | Lag air shutdown time | 0.0~20S |

| 19 | Program storage capacity | 1~100 |

| 20 | Program section | 1~12 sections |