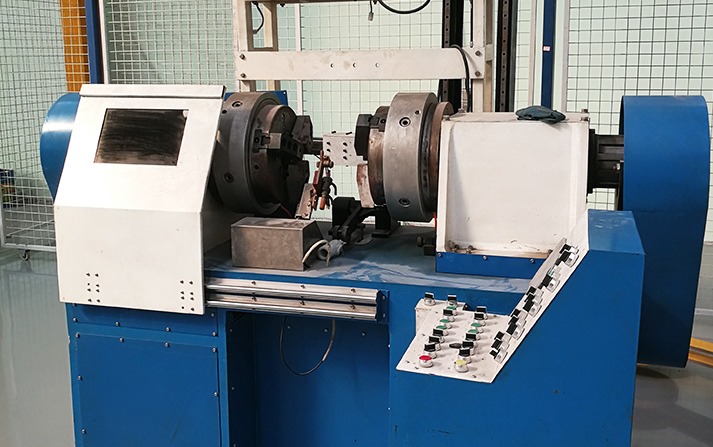

KHGT pipe to pipe butt welding machine

Application:

Advantage

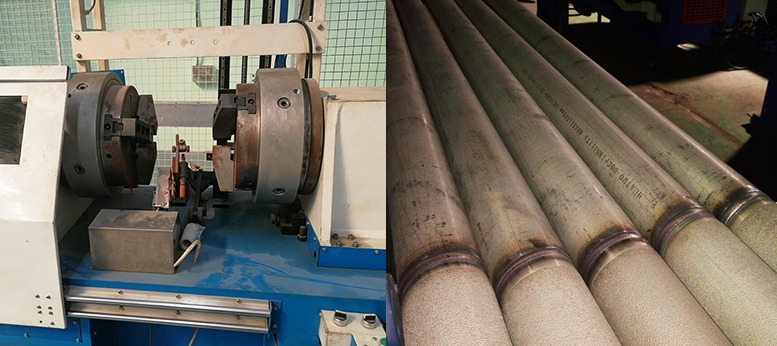

Suitable tube sizes: Normally 19 – 80mm

Suitable material: carbon steel, stainless steel, alloy steel, and so on.

KHGT have OSC/AVC functions – with oscillation OSC and arc voltage control AVC.

KHGT could solve the issue of operator error in gas tungsten arc welding(GTAW/TIG).

KHGT is composed of the power supply,control system,cooling system, wire feeding system, and the welding head working station.

KHGT can rotate freely infinite at any angle of 360°.

KHGT is widely adopted in pipeline fabrication, pipeline producing.

Driving and wire adopts reliable stepping motors.

Suitable for various kinds of pipe – pipe joint way, and various groove form

Starting main components are used aviation materials, light weight, size stability, and high temperature deformation

24 hours continuous welding- Welding torch using forced circulation water cooling, can work long hours. Mandatory water cooling system, equipped with 16 liters stainless steel water tank, not affected by field water hydraulic conditions of limits, cooling fully, reliable convenient.

Intelligent welding- PLC control system and LCD touch human-machine interface, can be stored up to 100 groups of welding programs, each group of welding scope can divide 1-2 section, input is simple, do not need professional basis and specialized welding knowledge.

Parameter

Welding head working station

| Model | KHGT-T-C-80 | KHGT-T-H-80 | KHGT-T-M-80 |

| Welding method | cold wire TIG | hot wire TIG(as option) | TIG+MIG(as option) |

| Tube diameter | 19-80mm | 19-80mm | 19-80mm |

| Normal tube thickness | 1.5-8mm | 1.5-15mm | 3-15mm |

| Welding speed | 0.1-5rpm 80-150mm/min | 0.1-5rpm 250-400mm/min | 0.1-5rp 250-400mm/min |

| Wire feeding speed | 0-3000mm/min | 0-8000mm/min | TIG:0-3000mm/min MIG:0-15000 mm/min |

| Wire diameter | 0.8,1.0,1.2mm | 0.8,1.0,1.2mm | 0.8,1.0,1.2mm |

| Adjustable angle | <90° | <90° | <90° |

Swinging function

| Biggest swing range | 10mm | 10mm | 10mm |

| Swing speeds | 0.5-10mm/s | 0.5-10mm/s | 0.5-10mm/s |

| Around retention time | 0.1-10s | 0.1-10s | 0.1-10s |

| Swing frequency | 0-5HZ | 0-5HZ | 0-5HZ |

Automatic arc length control

| Arc length adjustment speed | 2.5mm/s | 2.5mm/s | 2.5mm/s |

Power source and control system

| Rated input voltage | 380V±10% 3 phases, 50/60Hz |

| Rated input capacity | 13.9KVA |

| Rated power input | 13.2kw |

| Voltage allows range | ±10% |

| Load sustained rate | 400A 60% |

| 250A 100% | |

| Rated load voltage | 25V |

| Rated voltage no-load | 70V |

| Welding current adjusting range | 4-400A |

| Current rise time | 0.1-25S |

| Preheating time | 0.1-25S |

| Current decrease time | 0.1-25S |

| Pulse frequency | 0.5-500HZ |

| Argon gas flow | 8-12L/min |

| Built-in memory space | 100 groups of welding programs |

| Each set can be segmented number | 1-12 section |

| Cooling voltage | 1.2kgf/mm |