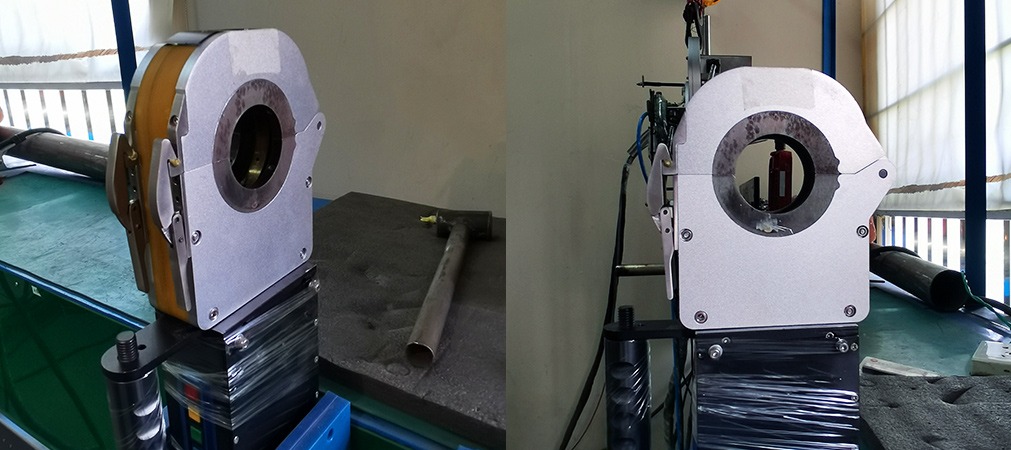

KHGC closed pipe automatic pulse argon arc welding machine

KHGC closed pipe automatic pulse argon arc welding machine

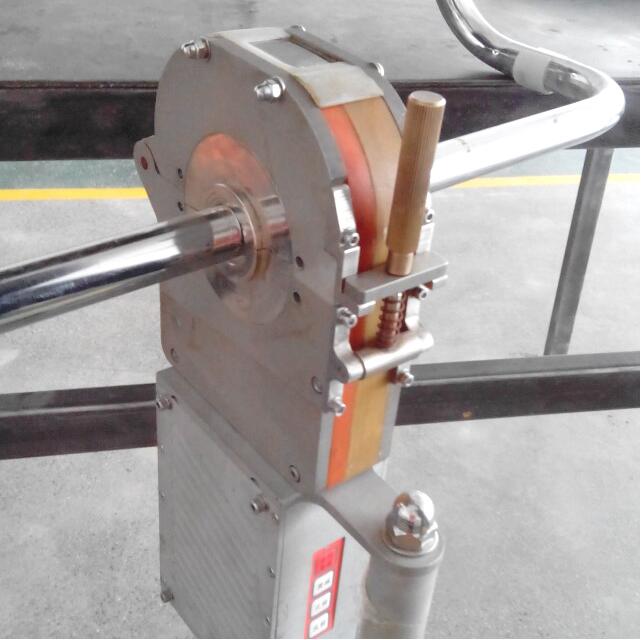

The KHGC pipe automatic welding machine is a full-position automatic pulse tungsten argon arc welding system designed for the butt jointing of various pipes; the KHGC series closed pipe-pipe fully automatic pulse argon arc welding machine can be used for pipes with outer diameters Ф3-Ф180mm. —Automatic welding of pipes in all positions. Especially suitable for welding carbon steel, alloy steel, stainless steel, and titanium alloy thin-walled pipes. Double clamping positioning, no positioning spot welding required.

Application:

Mainly used in pharmaceutical and chemical industry, food machinery, bioengineering, refrigeration engineering, electronic equipment, instrumentation, etc.

Advantage

During welding, the weld seam is sealed and protected, and the machine head cavity is filled with argon gas to ensure a stable protective environment. The weld bead is beautifully formed and there is no strong arc radiation during operation.

1. Suitable for welding carbon steel, alloy steel, stainless steel, and titanium alloy thin-walled tubes.

2. Double clamping positioning, good positioning effect, no need for positioning spot welding.

3. Adopting a closed design, the protection effect is good and the welds are beautiful.

4. The structural design is lightweight and suitable for assembly sites with small space.

Parameter

| model | KHGC12 | KHGC34 | KHGC63 | KHGC89 | KHGC114 | KHGC180 |

| Weldable pipe diameter (mm) | 3-12 | 10-34 | 12-63 | 16-89 | 20-114 | 51-180 |

| Rotation speed (rpm) | 0.6-10 | 0.6-10 | 0.6-10 | 0.3-5 | 0.1-2.5 | O.1-2.5 |

| Protective gas | Argon | Argon | Argon | Argon | Argon | Argon |

| cooling method | water cooling | water cooling | water cooling | water cooling | water cooling | water cooling |

| Weight (kg)(cable not included) | 1.2 | 2.1 | 2.1 | 3.2 | 6 | 9.8 |